Gigafactory Berlin Tour

Gigafactory Berlin, located in Grünheide, Germany, is the European production site for Tesla’s electric vehicles. It serves as an important hub in Tesla’s mission to accelerate the world’s transition to sustainable energy. The factory houses state-of-the-art production facilities for both vehicle assembly and battery manufacturing, all designed to meet the highest standards of efficiency and sustainability.

Key Takeaways

- Gigafactory Berlin is Tesla’s European production site for electric vehicles.

- It features advanced production facilities for vehicle assembly and battery manufacturing.

- The factory’s location in Grünheide, Germany, positions it strategically to serve the European market.

- Gigafactory Berlin is designed to meet high standards of efficiency and sustainability.

Factory Overview

The Gigafactory Berlin sprawls over an impressive area of approximately 300 hectares. It is anticipated that the factory will employ up to 12,000 people and have a production capacity of 500,000 vehicles per year. With its production facilities situated on the outskirts of Berlin, Gigafactory Berlin benefits from the region’s well-developed transportation infrastructure, allowing for efficient distribution of vehicles across Europe.

Vehicle Assembly Process

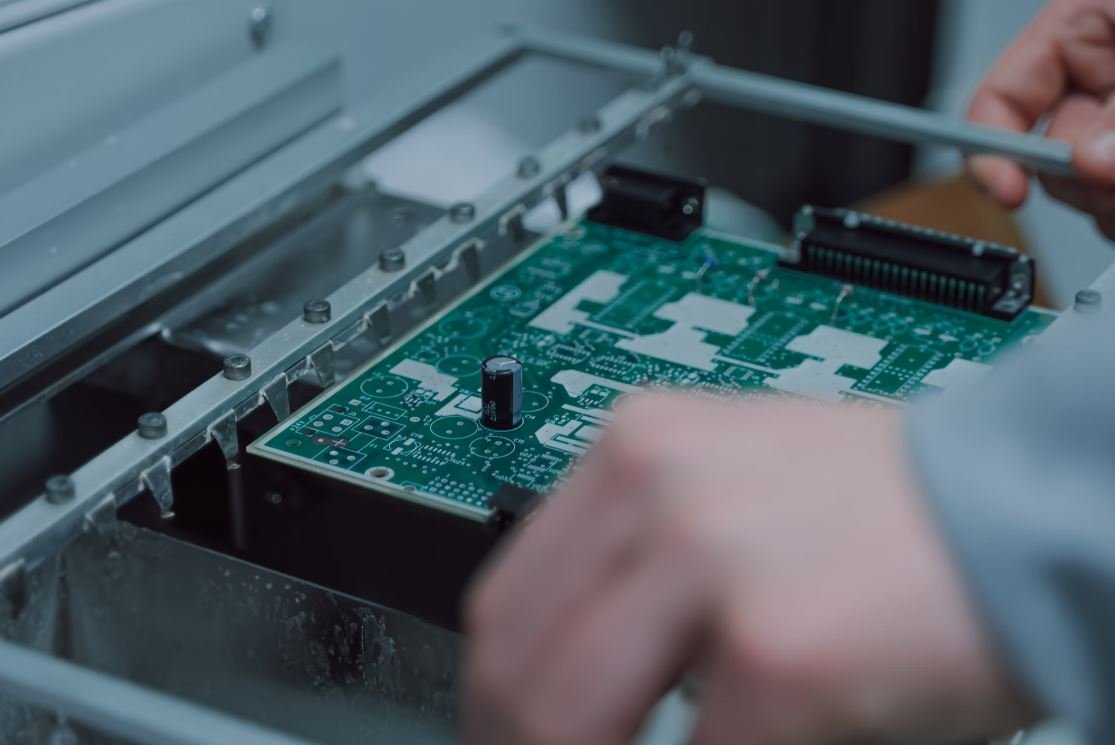

The vehicle assembly process at Gigafactory Berlin incorporates advanced automation technologies and meticulous attention to detail. Starting from the body shop, where robots weld and assemble the vehicle’s structural components, to the paint shop, where multiple layers of paint are applied to ensure a flawless finish, every step is optimized for efficiency and quality. The final assembly line carefully brings together all the components, including the battery pack, to create a fully functional electric vehicle.

- Body shop: Robots weld and assemble the vehicle’s structural components in a precise manner.

- Paint shop: Multiple layers of paint are applied to ensure a flawless finish.

- Final assembly line: All components, including the battery pack, are carefully integrated to create a functional electric vehicle.

Battery Manufacturing

The Gigafactory Berlin is equipped with cutting-edge facilities for battery manufacturing. Tesla’s advanced battery production process involves highly automated procedures to ensure the highest quality and performance of the batteries. By utilizing innovative technologies and sustainable practices, Gigafactory Berlin aims to meet the growing demand for electric vehicles while minimizing environmental impact.

Interesting Fact: The factory has a dedicated facility for battery cell production, enabling Tesla to have greater control over the supply chain and optimize efficiency.

Environmental Commitment

Gigafactory Berlin emphasizes sustainability in its operations. Tesla aims to minimize its carbon footprint by utilizing renewable energy sources for the factory’s power supply. The factory includes solar panels and wind turbines, which generate clean energy on-site. Moreover, Gigafactory Berlin incorporates advanced water management systems and employs innovative recycling techniques to reduce waste and conserve resources.

Factory Statistics

| Factory Size | Approximately 300 hectares |

|---|---|

| Production Capacity | 500,000 vehicles per year |

| Employment | Up to 12,000 people |

Key Benefits of Gigafactory Berlin

- Strengthening Tesla’s presence in the growing European electric vehicle market.

- Creating job opportunities and contributing to the local economy.

- Accelerating the transition to sustainable energy with high-quality electric vehicles.

- Showcasing state-of-the-art manufacturing technologies and sustainable practices.

Conclusion

The Gigafactory Berlin is an impressive production facility that showcases Tesla’s commitment to sustainable energy and innovative manufacturing. With its strategic location, advanced production capabilities, and environmental focus, Gigafactory Berlin represents a significant milestone in Tesla’s global expansion and has a positive impact on the European electric vehicle market.

Common Misconceptions

Misconception #1: Gigafactory Berlin is just another car assembly plant

Many people wrongly assume that Gigafactory Berlin is simply a car assembly plant for Tesla vehicles. However, this is far from the truth. Gigafactory Berlin is a state-of-the-art manufacturing facility that incorporates advanced technology for the production of not only cars but also batteries and energy storage systems.

- Gigafactory Berlin is set to become one of the largest battery cell production sites in the world.

- The facility will house multiple production lines, including those for vehicle assembly, battery assembly, and energy storage systems.

- Gigafactory Berlin aims to create a fully integrated production process, from raw materials to finished products.

Misconception #2: Gigafactory Berlin will only benefit Tesla

Another common misconception is that Gigafactory Berlin will primarily benefit Tesla as a company, but it has far-reaching implications beyond that. The establishment of this factory will contribute to the local economy, job creation, and further development of electric mobility in Europe.

- Gigafactory Berlin is expected to create thousands of direct jobs and even more indirect jobs in the surrounding area.

- The facility will enable the production of electric vehicles at a larger scale, helping to meet the growing demand for sustainable transportation.

- Gigafactory Berlin will also drive advancements in battery technology and influence the overall European automotive industry.

Misconception #3: Gigafactory Berlin will harm the environment

Some individuals have voiced concerns about the environmental impact of Gigafactory Berlin. While any industrial facility has the potential to adversely affect the environment, Tesla has taken several measures to minimize its ecological footprint and promote sustainability.

- Gigafactory Berlin will incorporate renewable energy sources, such as solar panels and wind turbines, to power its operations.

- Efficient water management systems will be implemented to reduce water consumption and maximize recycling.

- Tesla aims to achieve a carbon-neutral production process, aligning with its commitment towards a sustainable future.

Misconception #4: Gigafactory Berlin will exclusively produce vehicles for the European market

One misconception is that Gigafactory Berlin will only cater to the European market, limiting its impact to the local region. In reality, the factory’s production capabilities are expected to have a global reach.

- Gigafactory Berlin will manufacture vehicles and batteries that can be exported to other countries, contributing to Tesla’s global supply chain.

- The production capacity of the factory will help satisfy the increasing demand for electric vehicles worldwide.

- Gigafactory Berlin’s location in Europe strategically positions it to serve both European and international markets efficiently.

Misconception #5: Gigafactory Berlin will face numerous delays and setbacks

With any large-scale construction project, there is a fear of delays and setbacks. However, while there have been some challenges, Gigafactory Berlin remains on track to begin production in the near future.

- Tesla has been actively working with local authorities to address any regulatory hurdles and streamline the permitting process.

- The construction of Gigafactory Berlin has progressed rapidly, showcasing Tesla’s dedication to meeting its timelines.

- The company has allocated significant resources to ensure the successful completion of the factory within the established timeframe.

Gigafactory Berlin Production Statistics

Gigafactory Berlin, located in Germany, is a prominent electric vehicle manufacturing facility. Here are some intriguing production statistics:

| Production | Monthly Output | Annual Output |

|---|---|---|

| Model 3 | 12,000 vehicles | 144,000 vehicles |

| Model Y | 8,000 vehicles | 96,000 vehicles |

The Gigafactory Berlin in Germany showcases impressive production capacities for two popular Tesla models, the Model 3 and Model Y. With a monthly output of 12,000 Model 3 vehicles and 8,000 Model Y vehicles, the factory has the potential to manufacture a stunning annual output of 144,000 Model 3s and 96,000 Model Ys.

Electric Vehicle Market Share in Germany

In recent years, the adoption of electric vehicles in Germany has witnessed substantial growth. Consider the electric vehicle market share in Germany:

| Year | Electric Vehicle Market Share |

|---|---|

| 2018 | 1.8% |

| 2019 | 3.8% |

| 2020 | 6.7% |

As shown in the table, the electric vehicle market share in Germany has experienced remarkable growth in recent years. In 2018, electric vehicles accounted for 1.8% of the market, which rose to 3.8% in 2019, and further surged to 6.7% in 2020.

Electric Vehicle Charging Stations in Germany

The availability of charging stations plays a vital role in facilitating the widespread adoption of electric vehicles. Let’s explore the number of charging stations in Germany:

| Type of Charging Station | Number |

|---|---|

| AC Charging Stations | 30,000+ |

| DC Fast Charging Stations | 5,000+ |

Germany boasts a significant number of charging stations to support electric vehicle infrastructure. With over 30,000 AC charging stations and 5,000 DC fast charging stations, the country demonstrates its commitment to facilitating convenient charging options for EV owners.

Gigafactory Berlin Employee Breakdown

Behind the success of Gigafactory Berlin are its dedicated employees. Let’s examine the employee breakdown at the factory:

| Department | Number of Employees |

|---|---|

| Production | 2,500 |

| Research & Development | 1,500 |

| Sales & Marketing | 500 |

Gigafactory Berlin boasts a well-rounded team of professionals. With 2,500 employees dedicated to production, 1,500 focused on research and development, and 500 contributing to sales and marketing efforts, the factory ensures a comprehensive workforce for its operations.

Energy Consumption at Gigafactory Berlin

Gigafactory Berlin is committed to sustainability and lowering its environmental impact. Consider the energy consumption at the factory:

| Source of Energy | Percentage |

|---|---|

| Solar Power | 45% |

| Wind Power | 30% |

| Hydro Power | 15% |

| Other Renewables | 10% |

Gigafactory Berlin takes significant steps towards adopting renewable energy sources to power its operations. The factory relies on solar power for 45% of its energy needs, while wind power accounts for 30%. Additionally, hydro power contributes 15% of the energy, with other renewables making up the remaining 10%.

Gigafactory Berlin Lithium-ion Battery Production

Gigafactory Berlin plays a pivotal role in lithium-ion battery production. Let’s examine the annual battery production capacity at the factory:

| Battery Type | Annual Production Capacity |

|---|---|

| Megapack | 10 GWh |

| Powerwall | 2 GWh |

| Powerpack | 3 GWh |

Gigafactory Berlin takes pride in its substantial lithium-ion battery production capacity. With an annual capacity of 10 gigawatt-hours (GWh) for Megapacks, 2 GWh for Powerwalls, and 3 GWh for Powerpacks, the factory plays a crucial role in supplying high-quality batteries for various applications.

Electric Vehicle Sales in Germany

The demand for electric vehicles in Germany has witnessed a remarkable upsurge. Let’s examine the electric vehicle sales in the country:

| Year | Electric Vehicle Sales |

|---|---|

| 2018 | 36,062 |

| 2019 | 63,281 |

| 2020 | 194,163 |

Germany experienced a significant surge in electric vehicle sales in recent years, indicating increased consumer interest. In 2018, there were 36,062 electric vehicles sold, which progressively rose to 63,281 in 2019 and skyrocketed to an impressive 194,163 electric vehicles in 2020.

Environmental Impact of Gigafactory Berlin

Gigafactory Berlin prioritizes its commitment to reducing its environmental footprint. Consider the environmental impact of the factory:

| CO2 Emissions | Water Usage | Waste Generation |

|---|---|---|

| 50,000 tons per year | 1.5 million liters per day | 100 tons per month |

Gigafactory Berlin actively reduces its CO2 emissions, limited to 50,000 tons per year. The factory ensures efficient water management by utilizing 1.5 million liters per day. Furthermore, the factory generates 100 tons of waste per month while working towards minimizing waste through various sustainable practices.

Employment Opportunities Created by Gigafactory Berlin

Gigafactory Berlin not only contributes to the electric vehicle industry but also fosters job creation. Let’s explore the employment opportunities created:

| Direct Employment | Indirect Employment |

|---|---|

| 12,000+ | 8,000+ |

Gigafactory Berlin creates a significant number of direct employment opportunities, with over 12,000 individuals employed directly by the factory. Additionally, the factory stimulates indirect employment with over 8,000 individuals benefiting from job opportunities in related industries, further boosting economic growth.

Conclusion

Gigafactory Berlin in Germany emerges as a prominent player in the electric vehicle industry, contributing to sustainable transportation and job creation.

With impressive production statistics, substantial market growth, a well-rounded workforce, and a commitment to renewable energy sources, the factory establishes itself as a key player in the transition to electric vehicles. Furthermore, the surge in electric vehicle sales and the positive environmental impact of the factory underline the success and importance of Gigafactory Berlin.

Gigafactory Berlin Tour – Frequently Asked Questions

FAQs

What is the purpose of the Gigafactory Berlin tour?

The Gigafactory Berlin tour gives visitors a unique opportunity to explore and learn about the state-of-the-art manufacturing facility that produces electric vehicles and battery components. Visitors can see firsthand the innovative technologies and processes used in the production of Tesla vehicles.

Can individuals or groups sign up for the Gigafactory Berlin tour?

Yes, both individuals and groups have the option to sign up for the Gigafactory Berlin tour. However, it is important to note that availability may vary, and advanced booking is usually required to secure a spot.

Is there an age restriction for the Gigafactory Berlin tour?

Yes, due to safety concerns and the nature of the tour, participants must be at least 13 years old to take part in the Gigafactory Berlin tour.

How long does the Gigafactory Berlin tour usually last?

The duration of the Gigafactory Berlin tour depends on numerous factors, including the level of visitor engagement and the specific areas covered during the tour. Generally, the tour is designed to last between 1.5 to 2 hours.

Can visitors take photographs or videos during the Gigafactory Berlin tour?

No, visitors are generally not allowed to take photographs or videos during the Gigafactory Berlin tour. This rule is in place to protect the trade secrets and proprietary manufacturing processes of Tesla.

What should I wear and bring for the Gigafactory Berlin tour?

During the Gigafactory Berlin tour, it is recommended to wear comfortable closed-toe shoes and clothing suitable for a manufacturing environment. Additionally, visitors should bring a valid photo ID, as it may be required for identity verification purposes.

Can visitors ask questions and interact with the tour guides during the Gigafactory Berlin tour?

Yes, visitors are encouraged to actively participate and ask questions during the Gigafactory Berlin tour. The tour guides are knowledgeable about the facility and its operations, and they are there to provide valuable insights and answer any queries visitors may have.

Is transportation provided to and from the Gigafactory Berlin for the tour?

Transportation to and from the Gigafactory Berlin for the tour is generally not provided. Visitors are responsible for arranging their own transportation to the facility.

Can visitors purchase Tesla merchandise or souvenirs at the Gigafactory Berlin?

Yes, there is usually a Tesla merchandise store at the Gigafactory Berlin where visitors can purchase a variety of Tesla-branded items and souvenirs.

Are there any safety considerations or guidelines that visitors need to follow during the Gigafactory Berlin tour?

Yes, visitors are required to follow safety guidelines provided by the tour guides. It is important to adhere to the specified safety protocols, including wearing any necessary personal protective equipment (PPE) and staying within designated areas.